Infill patterns inspired by sandwich structures for sustainable material use in additive manufacturing

Researchers from the Institute of Engineering Design (KTmfk) have published a novel method for improving infill structures in additive manufacturing in the journal Materials. The article, entitled A New Slicer-Based Method to Generate Infill Inspired by Sandwich-Patterns for Reduced Material Consumption, offers an innovative approach to the resource-efficient production of 3D-printed structures.

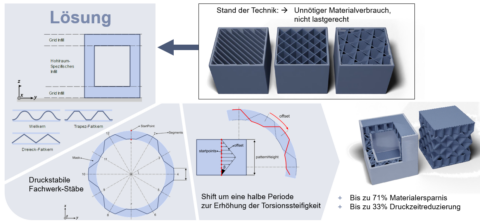

The method presented is based on the idea of optimizing material usage and stiffness through a sandwich-like, corrugated infill design. Unlike conventional infill patterns, which are often uniform, homogeneously distributed and load-independent, a geometry-awareness solution is pursued with this method. By hollowing out the components to be printed and then placing periodic pattern shapes between the resulting inner and outer shells, the bending and torsional stiffness is increased while material consumption and printing time are drastically reduced. In simulations, the new infill pattern was able to reduce material consumption by up to 77% and printing time by up to 78%. The method developed can be integrated directly into the slicer software to be used and is therefore accessible to a broad user group – from research institutions to industrial practice

https://doi.org/10.3390/ma17225596