Cooperation with Swinburne University (Melbourne, Australia) shows latest simulation results for composite laminates

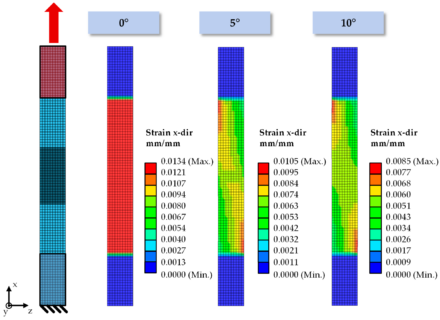

The use of components made of carbon fiber reinforced plastic (CFRP) is steadily increasing. With these higher quantities, variation management during product development is becoming increasingly important. In this study, artificial fiber misalignment has been introduced into the outer plies of tensile specimens to explore the influence of such variations on the mechanical properties. The collaboration started in October 2022 with the production of samples to calibrate and optimize the material parameters of the developed simulation model, in which Prof. Sandro Wartzack contributed significantly during his research semester in Australia. The effects of the artificially induced variation were evident in both the test data and the simulation models. Furthermore, the simulation models showed a good agreement with the experimental data, which allows the conclusion that the measurement methods used are well suited to characterize the fiber misalignment. The developed simulation models can be used to investigate the effects of fiber misalignment as part of the product development process without the need for physical testing.