Completed KTmfk joint project to develop a new type of lightweight partition wall for aircraft as part of the Central Innovation Program for small and medium-sized enterprises (ZIM)

Lightweight design is particularly important in the aviation industry. Therefore, the exploration of new lightweight potential is being strongly promoted in this sector. Potentials arise, for example, from the use of lightweight materials and the optimal structural-mechanical design of parts.

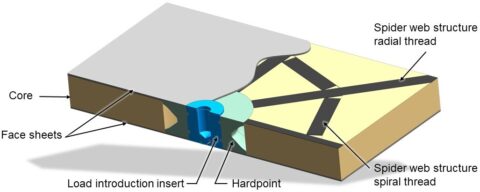

This is where the ZIM project “Spider web fiber-reinforced plastic: Development of a new type of lightweight partition wall for aircraft based on a new type of load application made of thermoset hardpoints and fiber-reinforced plastic tapes with a spider web structure to achieve weight savings of at least 5%” (KK5059905AT0) came in. The aim of the project was to develop a new type of aircraft partition wall based on fiber-reinforced lightweight structures with a 5% reduction in mass compared to conventional solutions and at least 20% faster production. Previously available solutions were based on sandwich structures in which load inlets (hardpoints) made of aluminum or hard metal were inserted in a manual process. In addition to a drastic increase in production costs, this also undermined the weight advantage of sandwich structures. Therefore, new types of hardpoints made of thermoset resins were developed, for which, in addition to an injection molding process, new types of injection molding tools with one additive and one machined component were also studied. In addition, suitable geometries of spider web-like structures made of glass- or carbon-fiber-reinforced plastic were developed. The combination of thermoset hardpoints and the spider web structure of the lightweight materials enabled uniaxial force distribution. Thus, it can replace the conventional solid metal inlets, which have higher tensile strengths than thermosets. With the new technology developed through the joint project with partners 3D ICOM Technologies GmbH & Co. KG, KMS GmbH & Co. KG and the Institute of Lightweight Engineering and Polymer Technology at TU Dresden, the aircraft partition wall made of lightweight structures leads to improved exploitation of the lightweight design potential in aircraft.